- Welcome to FS International

- Certified : ISO 9001: 2015

FS International is actively engaged in delivering high-end technical solutions & supply chain services at the doorstep of Aluminium Foundry Industries. Everything we perform is backed by a skilled & knowledge-based team. We are committed to make Aluminium melting & die-casting process easier.

Primary and Secondary smelters

Extrusion Plants

Die-Casters

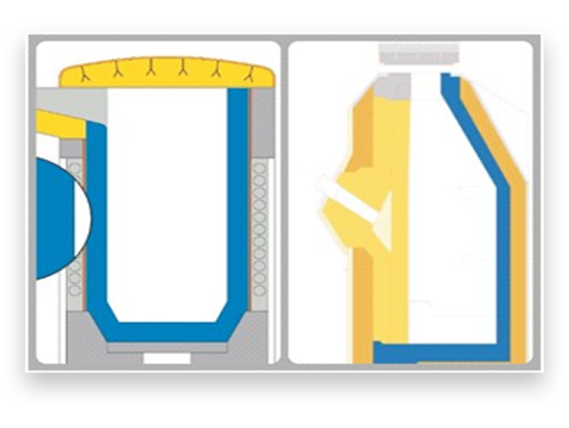

Dry neutral ramming mass for Induction furnaces for Aluminium melting

Wide range of Castables [both wettable & non-wettable] for lining & repair of all kinds of castable furnaces and transfer ladles

Non-wettable mastic patching material.

Powder fluxes

Granulated fluxes

Furnace wall cleaning fluxes

Best in class & wide range of metal cleaning fluxes

Reduces metal loss in dross thus improves metal yield

Environmentally friendly products

Helps in reducing landfills

Decrease the slag accumulated on the furnace linings and underneath

Damage to the furnace is reduced

Increases the service life of the furnace

Save the labor and power loss in furnace cleaning due to frequency of cleaning is minimized

Range of fluxes aids in eliminating “Na”, “Ca” & “Mg” removal to improve melt quality & metallurgical properties.

“Na” & “Ca” free fluxes helps in further improving melt cleaning efficiency.

“TiB” based grain refining fluxes.

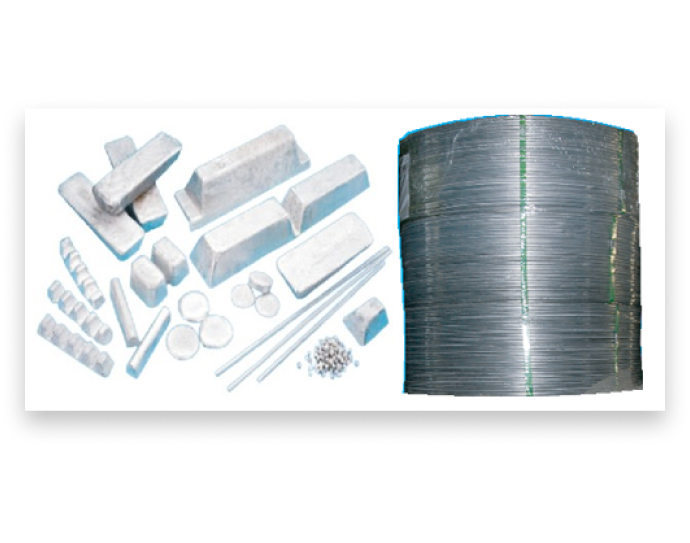

“AlTiB (5:1)” master alloys for grain refinement available in Coil,Cut rod & Waffle.

“AlTi (5% & 10%)” master alloys for grain refinement available in Ingots & Waffles

“AlSr 10%” master alloys for modification purposes available in Cut rods,waffle & Ingots.

“AlB(3%, 5% & 8%)” available in Ingots & waffles.

“Na” based powder or Granulated fluxes for modification purposes

“B” salt-based tablets for grain refiner

“AlMn(10%, 20% & 30%)” available in Ingots.

“AlFe(10%, 20%)” available in Ingots.

“AlMg(10%, 20%)” available in Ingots.

“AlCr(5%, 10% & 20%)” available in Ingots.

“AlZr(5% & 10%)” available in waffles & ingots.

“AlNi( 5% & 10%)” available in Ingots.

“AlSi(10%,30% & 50%)” available in Ingots.

“AlCu(10%, 20% & 30%)” available in Ingots.

“AlMn(10%, 20% & 30%)” available in Ingots.

“AlFe(10%, 20%)” available in Ingots.

“AlMg(10%, 20%)” available in Ingots.

“AlCr(5%, 10% & 20%)” available in Ingots.

“AlZr(5% & 10%)” available in waffles & ingots.

“AlNi( 5% & 10%)” available in Ingots.

“AlSi(10%,30% & 50%)” available in Ingots.

“AlCu(10%, 20% & 30%)” available in Ingots.

“ N2” based degassing tablets

“Hexa-Chloroethane” based degassing tablets

Graphite based rotors/impellors, shafts & baffles with different designs and sizes

Long-life Silicon carbide-based rotors/impellers, shafts & baffles with different designs and sizes

Promotes melt cleanliness

Lower energy costs by reducing heat loss

Improved process efficiency by reducing preheating time & faster turn around

Tape Cone for furnances.

Precast Non-wettable launders

Refractory lining based launders

Ready to use Patching material, gives improved safety and energy- efficiency

| Ceramic foam filter - Silicon Carbide (SiC) | Variable sizes |

| 10, 20 & 30 PPI's | |

| Ceramic foam filter - Alumina | Variable sizes |

| 10, 20, 30 & 40 PPI's | |

| Fibre-mesh Filters | Customized sizes |

Scrap control

Boost to productivity

Quality improvement

Water based Non-Wettable Refractory Coatings

Non-Wettable Zirconium based Coatings

Boron Nitride based non-wettable coatings

Conventional coatings.

Long Life coatings.

Long life Wheel mould coatings

Conventional die-coat's for GDC & LPDC

Long-life die-coat's for GDC & LPDC

Water-based die-lube's for HPDC

Graphite & Graphite-free plunger lubes for HPDC

Plunger beads for HPDC foundries

Anti-Soldering release agents

Acid based Anti-welding greases

Conventional & Long-life tool coatings

LPDC stalk-tube coatings

Lubricating Tool coatings

Ceramic insulating ladle coatings

Highly Insulated riser coatings for GDC & LPDC

Alumina based Coatings

Solvent based coatings for sand cores to control shrinkages

Tellurium based chilling coatings

Wide range of solvent & Water based coatings for sand cores surface finish

Core Joint adhesives (Hot to Hot & Hot to Cold conditions)

Sand core release agents

Solutions for Flow control in Extrusion Plants

Hot top rings

Floats

Bottom rings

Control pins

Filter Holder

Basin

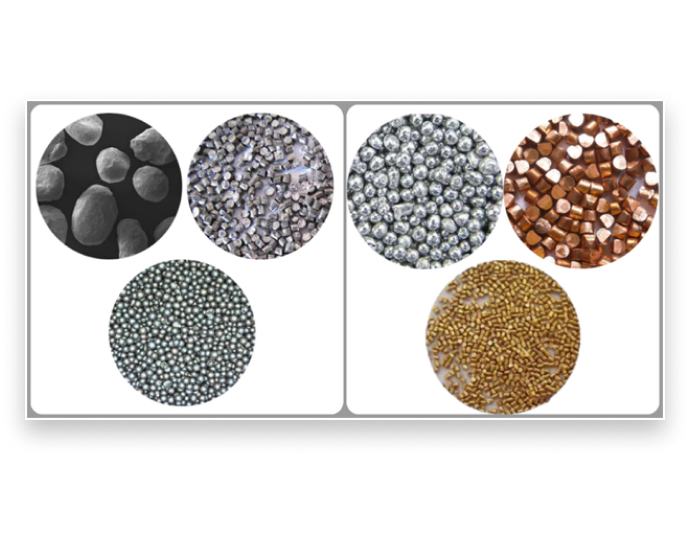

Stainless Steel Shots for shot blasting (both casted & cut wire shots)

Brass Shot Granules

Alumina Grit - All Sizes

Glass beads – All Sizes

Soft Iron powder specially designed for blasting of Dies & Moulds

Bright metallic surface of finished components

Achieves specific surface profile requirements

Dust generated is significantly reduced, lowering costs of disposal

Thermocouple's

Thermocouple wires

Protection tubes

GraphiteSilicon Carbide

Resistance Temperature Detector (RTD)

Pyrometer's

Experience, Commitment and Passion for the foundry industry are what describe us in the most apt manner.

Are you also passionate to improve the foundry operations and struggling with a lack of effective solutions? We are here, to work with you closely in a strategic and effective manner.

We are there to liten 24/7. Feel free to get in touch